Waste water disposal stations

| Waste water disposal stations |

- measuring the amount of waste water delivered

by sewer sanctions machines

- measurement of selected parameters

such as pH, conductivity, temperature, etc. - identification of waste water carriers by proximity cards

- automatic recording of data on each waste water discharge

- each plant version tailored to individual customer needs

- cooperation with a computer

(e.g. invoicing, process visualization, etc.) - possibility of waste water sampling

- possibility of setting quotas

- possibility of installing a pre-payment system for waste water delivery

- possibility of using solids shredders

Waste water disposal stations are used to collect municipal and industrial waste water from sewer sanctions machines. The stations allow you to specify the quantity of waste water supplied, its temperature, pH and conductivity. They identify carriers, as well as waste water providers. They also allow you to program a quota of waste water delivered.

Advantages of the STZ - type waste water disposal station:

- protection of a waste water treatment plant against destruction of activated sludge (bed)

- full automation and failure-free operation

- high quality, durability and reliability

- the container and metering skid made of stainless steel

- cooperation with a computer

- quick and easy installation

- tailored to individual user needs and terrain conditions

Waste water disposal stations consist- among other equipment - of metering skid and control system. Our systems meet all environmental requirements and require no protection zone. At the request of our customers we are able to equip the station with a sand separator, grate, sieve, screening press, etc. The disposal station operates in automatic (maintenance-free) mode. The station equipment can be installed in various heated containers or buildings at the customer’s request.

We are here to help you solve any technical problems that may occur during the design, installation, operation and modernization of facilities.

Additional equipment(optional) :

- Sieve

- Sieve and screening press

- Sampling system

- Prepaid system

- Shredder

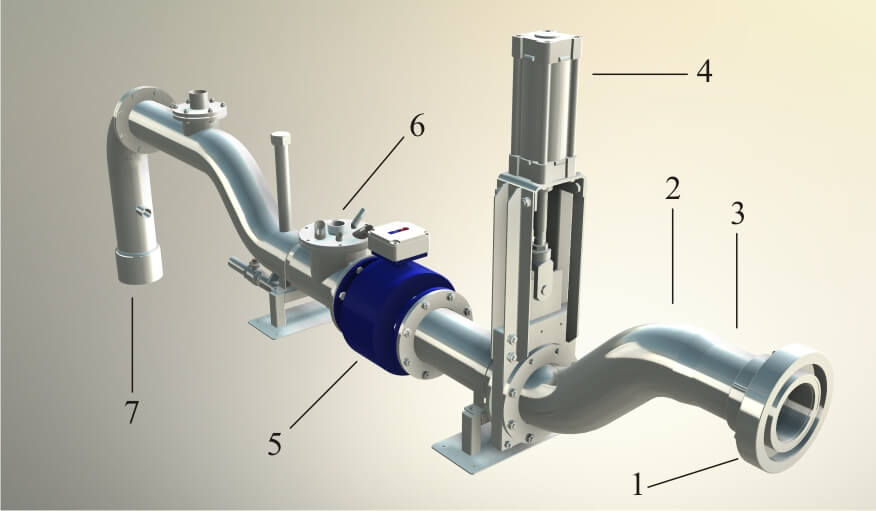

WASTE WATER DISPOSAL STATION SCHEME:

1. Connector

2.Metering skid

3. Inlet pipe

4. Pneumatic valve

5. Electromagnetic flow meter

6. Measuring module

7. Outlet pipe

Measurements taken during sewage drop:

- sewage volume

- pH

- temperature

- conductivity

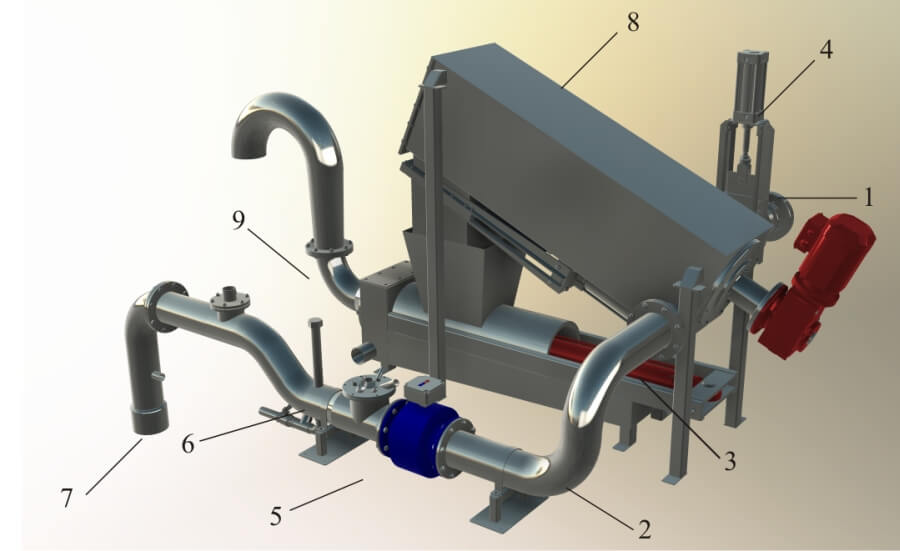

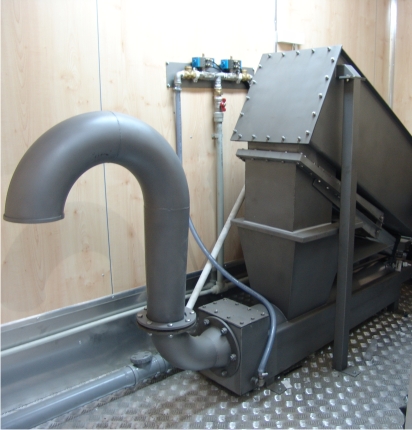

WASTE WATER DISPOSAL STATION WITH SIEVE AND SCREENING PRESS SCHEME:

1. Connector

2.Metering skid

3. Inlet pipe

4. Pneumatical valve

5. Electromagnetic flow meter

6. Measuring module

7. Outlet pipe

8. Sieve for screenings

9. Press for screenings

Description and principle of operation for the station with a sieve and screening press:

The station measures the amount of waste water supplied, as well as other selected parameters, protecting against exceeding the assumed values (in accordance with accepted requirements).

Waste water reception begins by connecting the sanctions machine hose to the sewage collection system with the connector. The carrier identifies himself by a transponder badge. Then the gate valve is opened and waste water flows into the sieve with screening press. Solid pollutants flowing with waste water settle on the sieve. A ribbon feeder scrapes the screenings from the sieve and transports them to charging hopper of the screening press. The screenings are pressed and moved outside into plastic bags or containers.

Then the waste water flows through the flow meter sensor and measurement module, in which the measurement of pH, conductivity and temperature takes place. If the physico-chemical parameters of waste water supplied do not fall within the given range of values, the gate valve can be automatically closed and the waste water disposal will stop immediately. In such case the waste water sampling is possible through the sampling system, and the sample can be sent for laboratory testing.

Total amount of waste water delivered is measured by the electromagnetic flow meter.

After

the waste water collection from one supplier the gate valve is

automatically closed, and a valve of the washing collector opens to wash

the system with water and thus prepare it for next waste water

reception. All data is saved on a memory card.

Operation of the entire system is managed by the control panel with printer and reader to quickly identify the supplier.

After each waste water discharge you can print a supply report, which will contain, for example:

1. Supplier No.

2. Dates and times

3. Overall amount of waste water supplied during a day

4. Amount of waste water currently supplied

5. pH, conductivity and temperature values

6. Sample No. (in case of using the automatic sampling system)

7. Quota of the fixed amount of waste water for the Customer (if the quota has been fixed)

Waste water disposal station types:

STZ 211 B2

1. Control panel

2. Electromagnetic flow meter

3.Metering skid with control system

-Cutting valve with pneumatic drive and with washing collector

-Supplying pipe with connector type"fireman"+ discharging pipe into collector with proper ended joint

4. Compressor

5. Measurement module: pH, conductivity, temperature

6. Reader for supplier identification

7. Identifiers for suppliers

8. "SODA” program - for data storage and supplier invoicing

9.Container type B with dimension2,0×1,0×2,0 m

STZ 211 A2S-with sieve and screnning press SWP

This version consists of:

1. Control panel

2. Electromagnetic flow meter

3.Metering skid with control system

-Cutting valve with pneumatic drive and with washing collector

-Supplying pipe with connector type"fireman"+ discharging pipe into collector with proper ended joint

4. Sieve with screening press

5. Compressor

6. Measurement module: pH, conductivity, temperature

7. Reader for supplier identification

8. Identifiers for suppliers

9. "SODA” program - for data storage and supplier invoicing

10.Container type A with dimension ~2×3,3×2,4 m

Office software assisting STZ operation:

- Deliveries reporting

- Suppliers administration

- Archive

- Parameters, configuration, data

Control system features:

- STZ menu operated through computer touch screen

- Several levels of data access

- Access protection by passwords

- Possibility of passwords change

- Data exchange through memory USB

- Software updating through memory USB

- Possibility to connect station to Ethernet

Additional equipment:

- proportionally in time function

- proportionally in flow function

-impulse ( on demand )

- at settled time/ date

- sample collection up to 8 m depth

- sample collection and its spilling into one 50 l container or bottle sets: 2 x 25l, 4 x 12,5l, 12 x 2l, 24 x 1l;

- high quality cooling system (air-cooled condenser, heat-insulating cover )

- enclosure resistant to adverse weather conditions

Sieve with screening press SWP

- Screening press PRE ( screening washing press PSW)

- Sand separator PSK

- Vortex sand trap PWE

- Integrated mechanical pre-treatment unit ZSP

- Screening shredder

- Sanitary station

- Stone catcher or board catcher type "Z"